Products

Manufacturer for Drum Sleeve - Polymer Nylon Materail Energy Saving And Insulation Lebus Sleeves For lifting Winch – Junzhong

Manufacturer for Drum Sleeve - Polymer Nylon Materail Energy Saving And Insulation Lebus Sleeves For lifting Winch – Junzhong Detail:

Advantage of the sleeve

our company developed LEBUS rope groove has obvious advantages. LEBUS rope groove suitable for multi-layer winding, can effectively reduce or avoid steel wire Rope disorder phenomenon. In the design process of the winch drum, the wire rope winding will effected by the winch drum has a large opening angel, bottom diameter selection, position of guide block, rope structure, rope groove spacing, rope groove the spiral Angle of the parallel section and the climbing section, so, the study of winch drum structure and characteristics, will help to reduce or avoid oil field field hoist drum disorderly rope phenomenon, prolong the use of wire rope and drum life.

The material of the sleeve

For efficiency and cost saving, the polymer drum sleeve developed and produced by our company adopts linear structural material with molecular weight of more than 1.5 million (the molecular weight of ordinary material is only 200,000 ~ 300,000) to process LEBUS rope groove, which is closely connected with the drum by spiral thread

Advantage of nylon material

High molecular nylon material light weight, impact resistance, low temperature resistance, self-lubrication, absorption of impact energy and other comprehensive characteristics. Polymer drum skin, mainly supporting imported drum and domestic large, super large drum drum hoist, prevent wire rope extrusion or bite wire rope damage, so that the wire rope can smooth transition between the layers

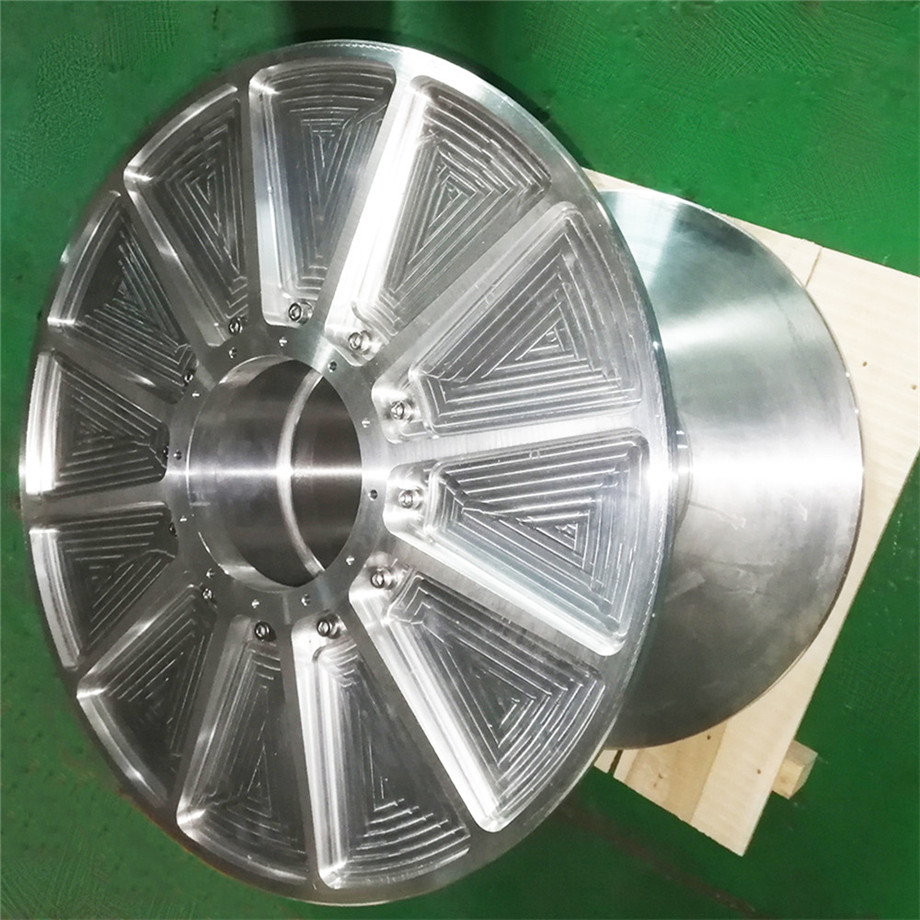

Product lookview

| PRODUCT NAME | multi-layer wire rope of cable onto hoisting drum spooling system lebus sleeves |

| PRODUCT OTHER NAME | Lebus groove sleeve |

| PROCESSING EQUIPMENT | CNC machining center |

| DRUM GROOVE ROTATION | Lefthand ,Righthand |

| SLING TYPE | Wire rope or cable |

| ROPE CAPACITY | 50-1000M |

| PRODUCT OTHER NAME | LBS groove drum or wire rope drum |

| MATERAIL | High polymer nylon or carbon steel |

| GROOVING TYPE | Lebus groove |

| WARRANTY | 1year |

Product detail pictures:

Related Product Guide:

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Manufacturer for Drum Sleeve - Polymer Nylon Materail Energy Saving And Insulation Lebus Sleeves For lifting Winch – Junzhong , The product will supply to all over the world, such as: Italy, Honduras, Uruguay, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.