Products

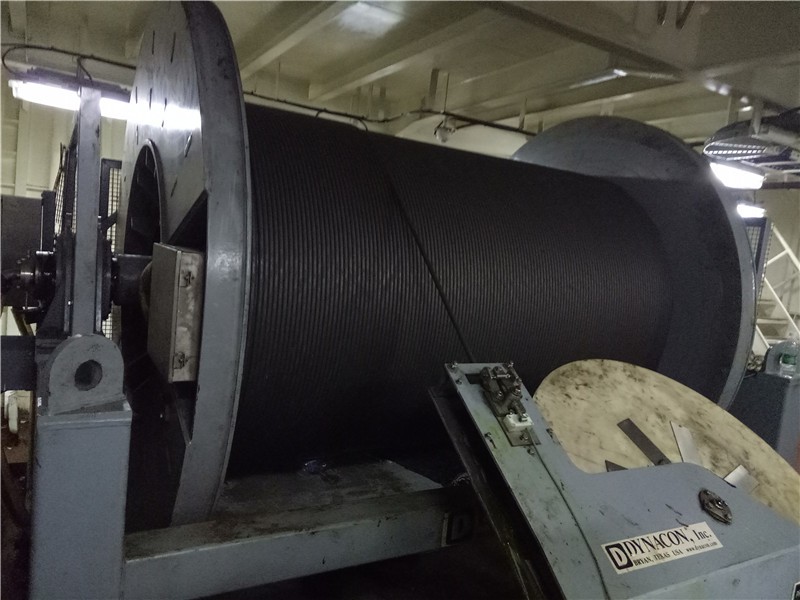

Best Price for Four Lifter Machine - offshore equipment 650KN eletric winch with CCS certification – Junzhong

Best Price for Four Lifter Machine - offshore equipment 650KN eletric winch with CCS certification – Junzhong Detail:

Electric winch is widely used in heavy work and large traction required. The motor of the single-drum electric winch drives the drum through the reducer, and a brake is arranged between the motor and the input shaft of the reducer. In order to meet the needs of lifting traction and rotary operations, there are double and multiple reel winches.

The structure

Electric winch is composed of base, gear box, motor, cable arrangement machinery, electrical control box, frequency converter box, hand-held controller and so on. The controller (or hand-held controller) is connected with the electrical control box by flexible wire.

installation of electric winch

The most important note here is the state of the rope drum, which must be used to ensure that the lasso is evenly wound before the process begins. The installation process is as follows:

1. Plug in the remote control. Connect the distal end of the first plug-in winch.

2. Do not let the remote connection hang. If you are a driver, operate the remote control from the driver’s seat and then make additional connections around the side mirrors of the car to make co-working easier.

3. Open the noose, use the remote control to open the noose a bit, and install it on the side of the electric winch.

Turn on the clutch. Please note that we have to open the hook later to open the clutch.

4. Hold the rope hook hand. Grabbing the hook with one hand pulls the rope out of the roller, so no matter how long the rope has been twisted, it doesn’t reach the hook.

5. Pull the rope on the pivot and lock the clutch.

So the electric winch is installed.

Working principle of electric winch

The electric winch converts electrical energy into mechanical energy through the motor, that is, the rotor of the motor outputs rotation and drives the drum to rotate after the triangle belt, shaft and gear deceleration.

The electric winch uses an electric motor as the power, drives the drum through an elastic coupling, a three-stage enclosed gear reducer, and uses an electromagnetic system.

applied range

Widely used in offshore platforms, petroleum machinery, water conservancy machinery, port machinery, large engineering machinery lifting equipment.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for Best Price for Four Lifter Machine - offshore equipment 650KN eletric winch with CCS certification – Junzhong , The product will supply to all over the world, such as: Leicester, Armenia, Canberra, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!